The S neox addresses the need for maximum measurement flexibility in an integrable sensor and is thus the most versatile industrial system on the market.

The S neox pushes versatility to the extreme: with 4-in-1 technology, providing unparalleled adaptability for shifty application requirements and maximum measurement flexibility on any surface. The re-design of some algorithms has increased the speed and capability of all technologies. The option to add a piezoelectric Z motor makes the S neox our top performer. The S neox also covers thicknesses measurements from 50 nm to 5 mm.

Files

| Attachment | Size |

|---|---|

| 7.56 MB |

News, events, promotions, webinars

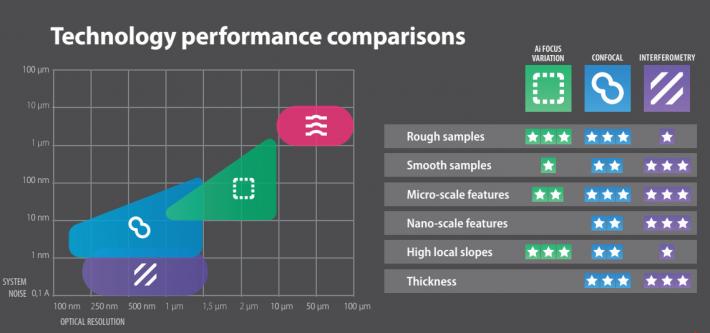

Ai Focus Variation

Active illumination Focus Variation is an optical technology that has been developed for measuring the shape of large rough surfaces. This technology is based on Sensofar's extensive expertise in the field of combined confocal and interferometric 3D measurements, and is specifically designed to complement confocal measurements at low magnification.

It has been improved with the use of active illumination to get more reliable focus location even on optically smooth surfaces.

Highlights of the technology include

- high slope surfaces (up to 86°)

- highest speed (up to 3mm/s)

- large vertical range measurements

Confocal

Confocal profilers have been developed to measure the surface height of smooth to very rough surfaces. Confocal profiling provides the highest lateral resolution, up to 0.15 μm line & space. With spatial sampling can be reduced to 0.01 μm, which is ideal for critical dimension measurements.

High NA (0.95) and high magnification (150X) objectives are available to measure smooth surfaces with steep local slopes over 70° (for rough surfaces up to 86°). The proprietary confocal algorithms provide vertical repeatability on the nanometer scale.

Interferometry

PSI - Phase Shift Interferometry has been developed to measure the surface height of very smooth and continuous surfaces with sub-Angstrom resolution, for all numerical apertures (NA). Very low magnifications (2.5X) can be employed to measure large fields of view with the same height resolution.

CSI - Coherence Scanning Interferometry uses white light to scan the surface height of smooth to moderately rough surfaces, achieving 1 nm height resolution at any magnification.

Spectroscopic Reflectometry

Thin film measurement technique measures the thickness of optically transparent layers quickly, accurately, non-destructively and requires no sample preparation. The system acquires the reflectance spectrum of the sample in the visible range, and is compared with a simulated spectra calculated by the software, with layer thickness modification until the best fit is found. Transparent films from 50 nm to 1.5 μm can be measured in less than one second. Sample evaluation spot diameter is dependent on the objective magnification which can be as low as 0.5 μm and up to 40 μm.

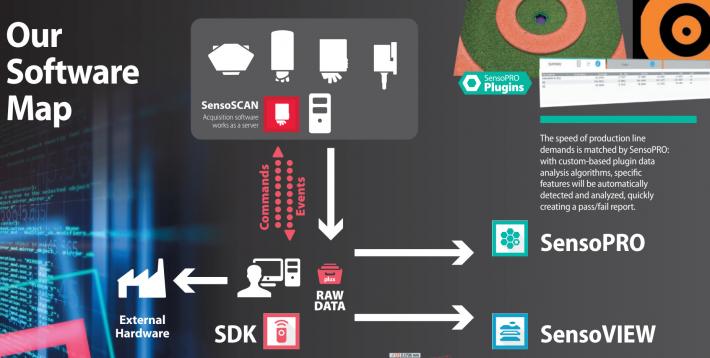

Senso Scan

Acquisition software - Works as a server. It outputs raw data.

SDK

The Software Development Kit (SDK) is a set of tools that enable remote control of one or even several sensors. It generates and manages communication between the client's computer and the sensors, in addition to addressing the acquired data to analysis software.

SensoPRO

The speed of production line demands is matched by SensoPRO: with custom-based plugin data analysis algorithms, specific features will be automatically detected and analyzed, quickly creating a pass/fail report.

SensoVIEW

SensoVIEW is the ideal software for a broad range of analysis tasks. It includes a comprehensive suite of tools for preliminary examination and analysis of 3D or 2D measurements, provides roughness or volume calculations and measures critical dimensions with a set of analysis tools, which can be exported as a report or data set (csv file)

A bench version of the S neox is also available. You can check all his features following the link here below.

Technical Features

Technologies | Confocal, PSI, ePSI, CSI, Ai Focus Variation and Thin Film |

FOV (single shot) | Up to 6.8 x 5.6 mm (1) |

Speed acq. | 4 s (2) |

Optical Resolution | Down to 148nm (3) |

System noise | Down to 0.01 nm (4) |

Weight | 10,1 Kg |

Cable length | 5 or 10 m |

Software comunication | DLL (C++ or C#, Windows 10® - 64 bits) XML (any operating system) |

Export files | SensoSCAN: Data: .plux, .dat Images: bmp |

MAG | 5X | 10X | 20X | 50X | 100X | 150X |

NA | 0.15 | 0.30 | 0.45 | 0.80 | 0.90 | 0.95 |

WD (mm) | 23.5 | 17.5 | 4.5 | 1.0 | 1.0 | 0.2 |

FOV (1) (mm) | 3378x2826 | 1689x1413 | 845x707 | 338x283 | 169x141 | 113x94 |

Spatial sampling (2) (µm) | 1.38 | 0.69 | 0.34 | 0.13 | 0.07 | 0.05 |

Optical resolution (3) (µm) | 0.94 | 0.47 | 0.31 | 0.18 | 0.16 | 0.148 |

System noise (4) (nm) | 100 | 30 | 8 | 5 | 3 | 1 |

Maximum slope (5) (º) | 9 | 17 | 27 | 44 | 64 | 72 |

MAG | 2.5X | 5X | 10X | 20X | 50X | 100X |

NA | 0.075 | 0.13 | 0.30 | 0.40 | 0.55 | 0.70 |

WD (mm) | 10.3 | 9.3 | 7.4 | 4.7 | 3.4 | 2.0 |

FOV (1) (µm) | 6756x5652 | 3378x2826 | 1689x1413 | 845x707 | 338x283 | 169x141 |

Spatial sampling (2) (µm) | 2.76 | 1.38 | 0.69 | 0.34 | 0.13 | 0.07 |

Optical resolution (3) (µm) | 1.87 | 1.08 | 0.47 | 0.35 | 0.26 | 0.20 |

System noise (4) (nm) | PSI/ePSI 0.1 nm (0.01 nm with PZT) CSI 1 nm | PSI/ePSI 0.1 nm (0.01 nm with PZT) CSI 1 nm | PSI/ePSI 0.1 nm (0.01 nm with PZT) CSI 1 nm | PSI/ePSI 0.1 nm (0.01 nm with PZT) CSI 1 nm | PSI/ePSI 0.1 nm (0.01 nm with PZT) CSI 1 nm | PSI/ePSI 0.1 nm (0.01 nm with PZT) CSI 1 nm |

Maximum slope (5) (º) | 4 | 7 | 17 | 24 | 33 | 44 |

- Maximum field of view with 3/2" camera and 0.5X optics

- Pixel size on the surface

- L&S: Line and Space, half of the diffraction limit according to the Rayleigh criterion. Spatial sampling could limit the optical resolution for interferometric objectives. Values for blue LED.

- System noise measured as the difference between two consecutive measures on a calibration mirror placed perpendicular to the optical axis. For interferometry objectives, PSI, 10 phase averages. The 0.01 nm are achieved with Piezo stage scanner and temperature-controlled room. Values for green LED (white LED for CSI). Values obtained in a VC-E vibration environment.

- On smooth surfaces. Up to 86° on rough surfaces.

Measuring principle | Confocal, PSI, ePSI, CSI, Ai Focus Variation and Thin Film |

Measurement types | Image, 3D, 3D thickness, profile and coordinates |

Camera | 5Mpx: 2448x2048 pixels (60 fps |

Confocal frame rate | 60 fps (5Mpx); 180 fps (1.2 Mpx) |

Vertical scan range coarse | Linear stage: 40 mm range; 5 nm resolution |

Vertical scan range fine | Piezoelectric scanner with capacitive sensor: 200 μm range; 1.25 nm resolution |

Max. Z measuring range | PSI 20 µm; CSI 10 mm; Confocal & Ai Focus Variation 34 mm |

LED light sources | Red (630 nm); green (530 nm); blue (460 nm) and white (575 nm; center) |

Nosepiece | 6 position fully motorized |

Sample reflectivity | 0.05 % to 100% |

Advanced Software Analysis | Inc: SensoVIEW; Op: SensoPRO, SensoMAP |

Software communication | DLL (C++ or C#, Windows 10® - 64 bits) - XML (any operating system) |

Computer | Latest INTEL processor |

Operating system | Microsoft Windows 10®, 64 bit |

Cable Length | 5 or 10 m |

Environment | Temperature 10 ºC to 35 ºC; Humidity <80 % RH; Altitude <2000 m |